Capabilities

At Northeast Mold & Plastics, we offer integrated services of standard injection molding that begin with the product development cycle. We have unique engineering strengths that allow us to address opportunities to innovate your product through design and technology. We have highly skilled tool design capabilities that ensure that your mold matches your production requirements. We know that to be successful on the molding floor, you must first be successful in the tool design.Our specialized core competencies include:

Product Development:

- Innovative Part Design Concepts

- Prototyping: SLA, SLS, Machining

- Cast Urethane MUD Units

(Master Unit Die)

Engineering & Tooling:

- Proficient and Highly Skilled Tool Design

- Domestic Tooling

- Asian Tooling

Injection Molding:

- Standard Injection Molding

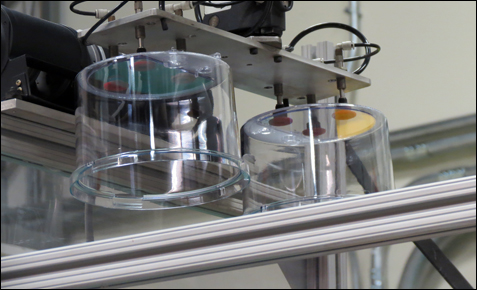

- Two Shot, Multi-Component, Multi-Material Molding

- Unscrewing Tools

- Caps & Closures

- Overmolding

- Insert Molding

Secondary Operations:

- Light Assembly - Cell Manufacturing

- Ultrasonic Welding

- Pad Printing

- Heat Staking

- Machining

Northeast Mold & Plastics has been a partner and an important customer of ARBURG dating back to the late 1980's. Since then, the local molder has purchased several of our machines, including 2-component machines, in an effort to standardize their facility and grow their tonnage and technical abilities. NE. Mold has relied on ARBURG to provide a quality product, timely service and technical support. We look forward to continuing our close relationship in the years to come and being part of their continued success.

John Ward - Vice President / Sales & Marketing, ARBURG Inc.

John Ward - Vice President / Sales & Marketing, ARBURG Inc.